Products

Multibusbar Flat Ribbon

M9-M12 round wire

Top - Bottom Busbar

-

Multibusbar Flat Ribbon

Multibusbar Flat Ribbon -

M9-M12 Round Wire

M9-M12 Round Wire -

Top – Bottom Busbar

Top – Bottom Busbar

It is widely used in the solar industry to connect solar cells together in a solar module. It is a thin and flexible tin/silver coated ribbon that is placed on the front and back of a solar cell and soldered to create a series connection between the cells.

PV interconnect Flat Ribbon

| width(mm) | 0.4 – 2.5 |

| Thickness(mm) | 0.1 – 0.35 |

| Standard Coating | 16μm – 25μm (single side) |

Available Coating Type

| Leaded Coating | Sn60Pb40 | Sn62Pb36Ag2 |

| ROHS COMPLIANCED (lead Free) Coating | Sn100 | Sn96.5Bi38Ag2 |

| SnAgCu | Sn60Bi38Ag2 |

Technical Parameter

| Elongation | ≥ 25% |

| Yield Strength | 55 – 70 N/mm² |

| Tensile Strength | 150 – 200 N/mm² |

| Camber Rate | ≤5mm/1000mm |

| Resistivity | ≤2.2 × 10⁻⁸ Ωm@20°C |

Specification of the Base Metal

| Copper Grades | Cu-ETP |

| Cu-OF | |

| Resistivity | 1.707 × 10⁻⁸ Ωmm²@20°C |

| Density | 8.89 gm/cm³ |

| Conductivity(100% min) | 101% |

Packing spool type

| HKV-160 (Bioconical) | 10S (Cylindrical) |

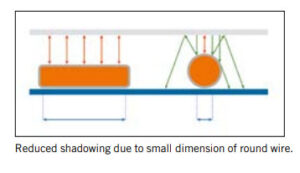

Round ribbons are responsible for conducting the direct current that the cells collected from solar photons to the solar inverter. Round ribbons first of all lead partially to reduce in the shading losses compared to flat ribbons. In addition to that, they also increase the reflectance of incident lights into the interface of the glass and the front encapsulant layer of a PV module. Therefore, the use of this technique can result in both increasing the output power and also the efficiency of the PV module.

Round ribbons are responsible for conducting the direct current that the cells collected from solar photons to the solar inverter. Round ribbons first of all lead partially to reduce in the shading losses compared to flat ribbons. In addition to that, they also increase the reflectance of incident lights into the interface of the glass and the front encapsulant layer of a PV module. Therefore, the use of this technique can result in both increasing the output power and also the efficiency of the PV module.

| Diameter(mm) | 0.3 – 0.5 |

| Standard Coating | 40μm (over all) |

| Leaded Coating | Sn60Pb40 | Sn62Pb36Ag2 |

| ROHS COMPLIANCED (lead Free) Coating | Sn100 | Sn96.5Bi38Ag2 |

| SnAgCu | Sn60Bi38Ag2 |

| Elongation | ≥ 20% |

| Yield Strength | 55 – 75 N/mm² |

| Tensile Strength | ≥ 150 N/mm² |

| Camber Rate | NA |

| Resistivity | ≥ 2.2 × 10⁻⁸ Ωm@20°C |

| Copper Grades | Cu-ETP |

| Cu-OF | |

| Resistivity | 1.707 × 10⁻⁸ Ωmm²@20°C |

| Density | 8.89 gm/cm³ |

| Conductivity(100% min) | 101% |

| HKV-160 (Bioconical) | 10S (Cylindrical) |

The busbar is connected to the perimeter of the solar module.The current generated by the solar panel is carried through an interconnect ribbon and transferred to a junction box via a busbar ribbon.

PV Busbar

The busbar is connected to the perimeter of the solar module.The current generated by the solar panel is carried through an interconnect ribbon and transferred to a junction box via a busbar ribbon.

PV Busbar

| width(mm) | 3.00 – 8.00 |

| Thickness(mm) | 0.1 – 0.4 |

| Standard Coating | 16μm – 25μm (single side) |

| Leaded Coating | Sn60Pb40 | Sn62Pb36Ag2 |

| ROHS COMPLIANCED (lead Free) Coating | Sn100 | Sn96.5Bi38Ag2 |

| SnAgCu | Sn60Bi38Ag2 |

| Elongation | ≥ 25% |

| Yield Strength | < 145 N/mm² |

| Tensile Strength | ≥ 150 N/mm² |

| Camber Rate | ≤ 5mm/1000mm |

| Resistivity | ≤ 2.2 × 10⁻⁸ Ωm@20°C |

| Copper Grades | Cu-ETP |

| Cu-OF | |

| Resistivity | ≤ 1.707 × 10⁻⁸ Ωmm²@20°C |

| Density | 8.89 gm/cm³ |

| Conductivity(100% min) | ≥ 101% |

| HKV-160 (Bioconical) | 10S (Cylindrical) |